Continuous line for the manufacturing of wall and roofing sandwich panels with the PIR Premier rigid core

Despite the apparently simple design, polyurethane foam (PIR Premier, PUR Classic) sandwich panels are exclusively a high-tech product. Deviations or skipping of single links in the technology sequence are absolutely intolerable. Every production section has its special strategic function, essential for the quality of the final product, which can be neither excluded nor minimized.

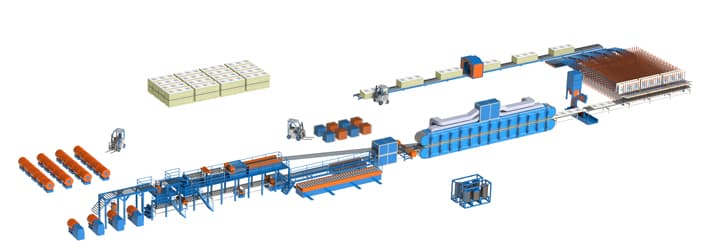

In 2012, the most modern in Russia continuous line was put into operation at the new plant of PH Insulation, for production of wall and roofing polyurethane foam PUR and fire-proof polyisocyanurate PIR sandwich panels, having the capacity of 2 500 000 square meters of sandwich panels a year.

Pu.Ma Group was chosen as the equipment supplier for the new plant, the Italian, being the world leader in the manufacturing of equipment for polyurethane foam products and possessing an exceptionally rich experience in this field.

The continuous line Pu.Ma installed at the PH Insulation plant, consists of a series of machines organized in functional groups and has the unified system for the process data management. The series includes the mechanisms for unreeling of the metal sheet, processing of the sheet with the coronary discharge, its profiling and heating, the equipment for mixing the chemical components and application of the primer and foam, the crawler press, cutting section and the finished product management section.

Preproduction

Lab control of incoming raw material and strict observation of all incoming parameters and technological modes.

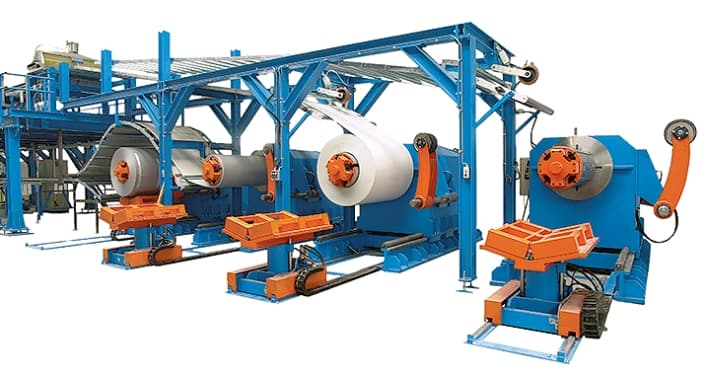

Unreeling of the metal sheet

The continuous metal list feeding system provides high operation speed and continuity.

Processing with the coronary discharge

Coronary discharge removes the static electricity from the metal sheet in order to improve the polyurethane foam adhesion.

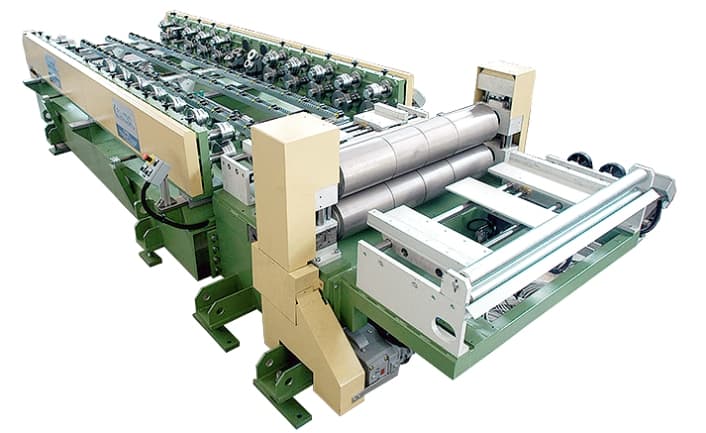

Profiling the metal sheet

The basic element of the machine group is the profiling mill, completed with the shafts, which determine the final panel shape. In case of necessity to produce different panel types, the group is integrated with the profiling equipment kit. In this case, it’s the operator, who chooses the appropriate profiling kit on the control panel. The section consists of 12 and 24 stands for wall and roofing panels respectively. The length of the section permits to shape the metal part of the panel with elevated precision, also minimizing the mechanical load on the coated surface.

Application of the primer

Preliminary application of a thin layer of glue, close in composition to the main material of foam, providing the elevated adhesion to metal.

Heating of the metal sheet

Preliminary heating of the metal sheet provides the necessary temperature conditions in order to obtain the ideal adhesion of the primer layer to the metal.

Storage and feeding of pentane

Pentane in used as foaming agent. It corresponds to the European ecological standards.

Component mixing, obtaining of foam

Two interchangeable dispensing heads provide the continuous manufacturing process. The foam is applied evenly on the primer layer all over the panel area, thanks to the differentiated speed of the dispensing head.

Crawler press

During the motion inside the 26-meter press, as the result of chemical components’ reaction and foam expansion limitation, the panel shape is formed. The horizontal planes of the press consist of perfectly even steel plates, which provide the constant panel thickness. The locking profile shape is obtained by means of the lateral stoppers system.

Cutting

The cutting section, equipped with the circular saw and deburring system, is completed with the aspiration for the chip removal. The saw speed is synchronized with the speed of the whole line, and it allows, even at the maximum speed, to cut panels from 2 meters long.

Cooler

The process of foam forming is not terminated at the exit from the crawler press, but it continues in the cooler designed for 28 positions at the panel length up to 15 meters.

Piler

Roofing panels are turned over by means of the tilter-piler in order to obtain compact stacks, which are submitted then, to the packing section.

Packer

Provides the automatic palleting and stretch film packing.

Warehouse of finished products

Since the foam formation process is not terminated after the exit from the line bud it continues then for about other 24 hours, the finished sandwich panels rest in the warehouse with controlled temperature conditions. This final cycle, as all the previous stages, is crucial for the formation of the appropriate shape of the panels.

Quality control

All the raw materials and every product of ProfHolod pass the strictest quality control in laboratory. For this reason, the test lab has been organized on the manufacturing site

Interested in selling PH Insulation products?

PH Insulation insulated panels and doors are used in 16 countries around the world from Germany to USA. If you want to leverage PH Insulation 15 years expertise on the market, impress your clients with top quality insulation products at a very attractive price and earn a premium with every sale, please fill a form below and we will be in touch with you shortly.