PH Insulation’s R&D Center has developed a new foaming adhesive for sandwich panels with mineral wool. The new material increases adhesion of insulator to metal by 10% compared to other adhesives used at the company’s manufacturing of sandwich panels. Since April 2023, the new adhesive is used in PH Insulation’s insulated panels.

PH Insulation started producing sandwich panels with mineral wool in 2019 after acquiring the second continuous line. PIR sandwich panels by PH Insulation are made with polyisocyanurate foam, and show highest rigidity ratios due to the deepest profiling on the market, 1.5 mm. They demonstrate over 150 kPa in tensile strength tests at a density of 40 kg/m3. However, the mineral wool behaves differently than PIR in sandwich panels – the material retains its size and needs to be glued to metal.

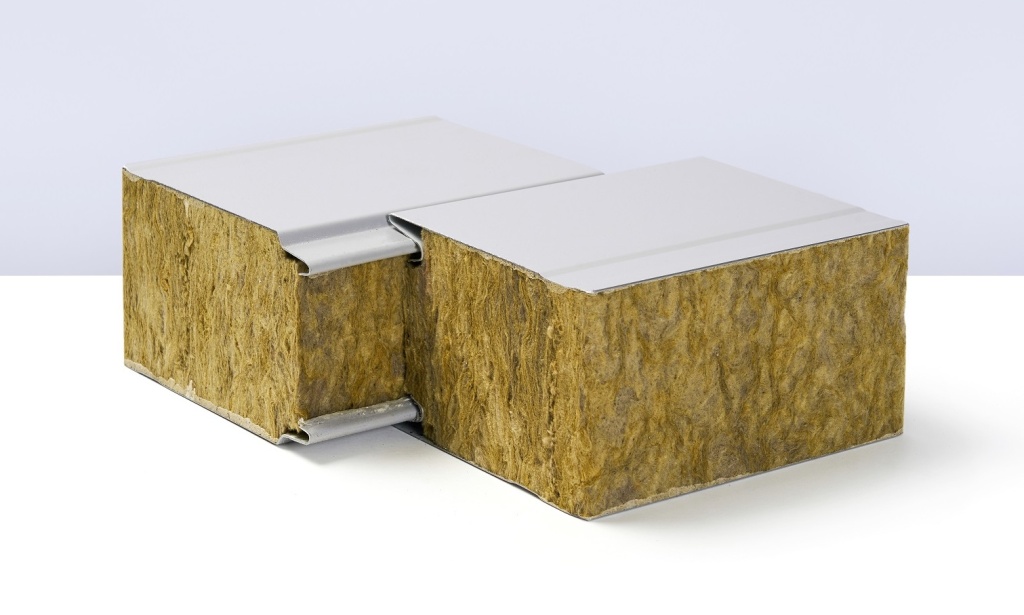

Polyurethane and polyisocyanurate foam expand during production of sandwich panels, and fill the whole internal space of a sandwich panel covering all irregularities, cavities and locks. The adhesive used in PIR insulated panels manufacturing only enhances the bonding between PIR and metal, but with mineral wool sandwich panels, the glue plays much larger role

Irina Pechenkina

Head of Research and Development Department of PH Insulation

Sandwich panels with mineral wool require an actively expanding adhesive designed to fill in all the irregularities that arise, when complex geometry profiles engage a flat surface of the mineral wool. The adhesive needs to provide direct surface contact with metal sheets and penetrate as deeply as possible into structure of the mineral wool, permeating the fibers to guarantee the highest physical and mechanical properties of the product.

PH Insulation’s R&D Center has deep expertise in the field of polyurethanes, so the new adhesive for sandwich panels has also been created with polyurethane. It took more than 12 months to derive the formula that delivers the best results. The R&D Center examined over 20 various combinations. During the tests, the adhesive was frozen to -25°C and heated to +300°C - with mandatory delamination experiments. Sandwich panels with the new adhesive endured physical and mechanical strength tests at the R&D Center, and withstood 14 cycles when they have been carried outside of the manufacturing building to check how the adhesive endures temperature changes.

Our sandwich panels with mineral wool and the new adhesive layer survived all possible tests before entering mass production. Now that the polyurethane commands the adhesion, you can be totally certain that it will deliver the best results you can get

Irina Pechenkina

Head of Research and Development Department of PH Insulation