In 2023, PH Insulation door and cold room production facility boosted its efficiency by 38% compared to 2022 by implementing lean manufacturing tools and techniques.

Lean manufacturing is a production management methodology focused on minimizing waste while maintaining or increasing productivity. Key principles of lean manufacturing include:

- optimizing production steps and eliminating waste

- reducing production cycle times

- enhancing product quality

- engaging employees in ongoing process improvement

Throughout 2023, heads of all PH Insulation departments underwent training to drive changes in culture, process management, and operational activities.

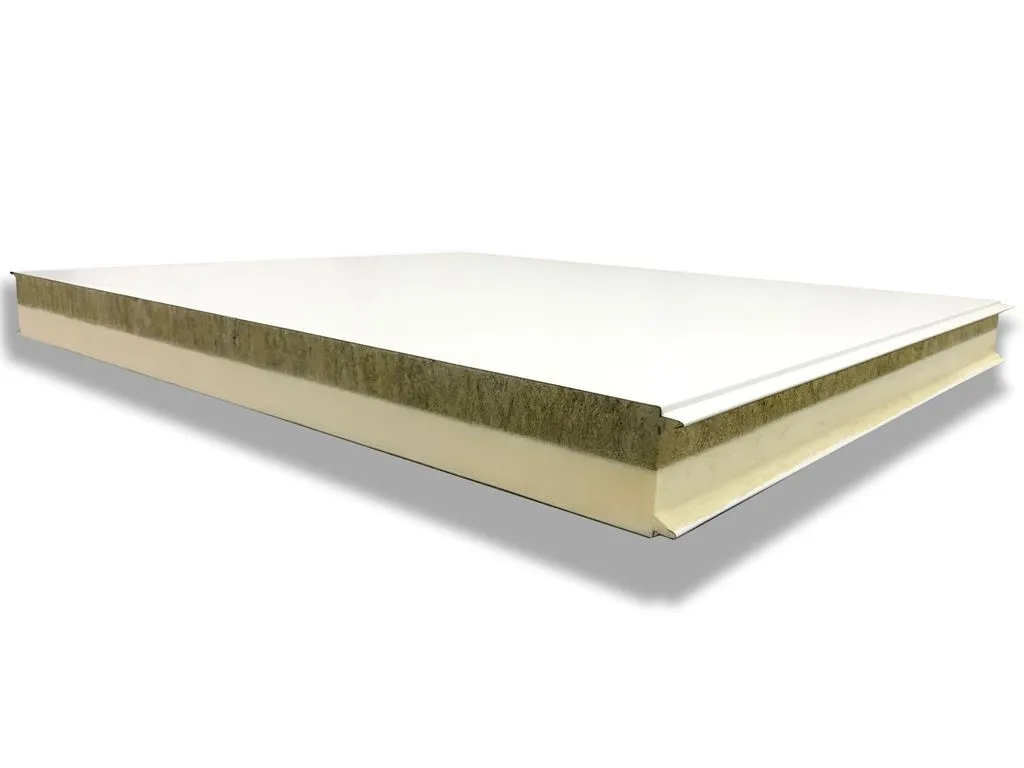

Systematic implementation of lean manufacturing techniques commenced with the 5S lean methodology in the PH Insulation workshop area for door and refrigerated cold rooms manufacturing. As a result

- production efficiency of the workshop increased 38% through the optimization of production logistics and standardization of workstations

- production output increased by 37%

- labor resource efficiency improved by 34%

- new business processes implemented

- excess material and semi-finished product inventory eliminate to ensure the most efficient use of workspace

- raw material flow streamlined

- employee safety enhanced

In 2023, we took the initial steps on the long road to embracing lean manufacturing practices through our plant, aiming for a qualitatively new level of management and increased efficiency. The early results are particularly important as they set the pace for innovation, which is essential for the sustainable development business model.

Askar Gilfanov

Operations Director of PH Insulation

In the near future, PH Insulation aims to complete the implementation of the 5S lean methodology company-wide as part of the overarching lean manufacturing concept and introduce new lean technologies, including quick changeover, also referred as SMED — a lean manufacturing technique designed to reduce time and waste involved in switching from one process or product to another.