PH Insulation has been utilizing solar energy for over 7 years, resulting in the prevention of more than 126 tons of CO2 emissions into the atmosphere, with 23 tons prevented in 2022 alone.

PH Insulation’s long-term environmental strategy is centered on expanding the use of solar energy to reduce impact on environment. PH Insulation has installed the largest solar power plant in the Shchelkovsky District has at company’s manufacturing site, and in 2023, up to 50% of the company's electricity needs will be provided by the sun.

PH Insulation’s mission is to provide science-intensive solutions for temperature management to significantly reduce energy and monetary waste. The company aims to set an example for customers and partners by demonstrating the benefits of energy saving technologies, such as energy-efficient materials with PIR Premier polyisocyanurate foam for constructing and insulating buildings, and renewable energy sources for further reducing electricity consumption.

Green power solution

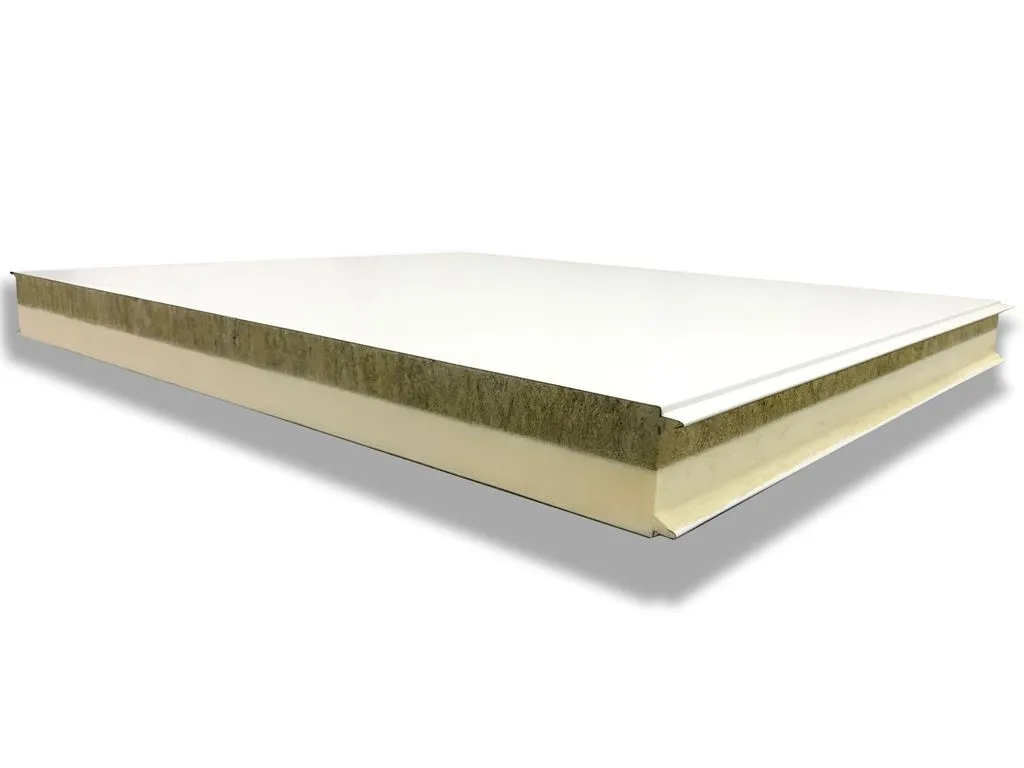

Starting from 2021, PH Insulation offers partners to install a green energy solution on new and already built facilities: the Solar Sandwich system. The system consists of sandwich panels with PIR Premier insulation and solar panels.

Reuse and recycling

The company also implements circular economy principles in its manufacturing process by reusing and recycling waste to improve waste management efficiency. In 2022, over 7,000 sq. m of polyurethane foam waste was utilized to create a universal granular insulator Kroshka PIR and polyurethane foam waste was used as cushioning material in the packaging of roofing sandwich panels.

Recyclable materials are sent for recycling, with over 90 tons of recyclable materials sent for recycling in 2022. PH Insulation employees collect paper and cardboard. Later the materials are sent for processing at the Sukhona Pulp and Paper Mill in the Vologda Region which produces cardboard from it. Scrap metal is moved to metallurgical plants for processing into metal.

Durability of polyurethane foam products

Polyurethane foam products have a proved service life of at least 50 years, during which they save 96 times more energy than it takes to produce them. PH Insulation is conducting a study on sandwich panels used in their buildings since 2015 to promote the durability and environmental friendliness of polyurethane foam and polyisocyanurate foam insulation. According to the results of the first study, the average value of the thermal conductivity of the insulator for all measurements was 0.0221 W/m*K. This confirms the exceptional reliability of PU insulation, which maintains its qualities over time.

Investing in technology for a sustainable future

PH Insulation is committed to invest further in developing new polyisocyanurate foam systems at the company’s R&D Center to create a new Russian PIR system with increased fire resistance and minimal thermal conductivity pursuing to increase the use of PIR sandwich panels in constructing modern energy-efficient buildings.