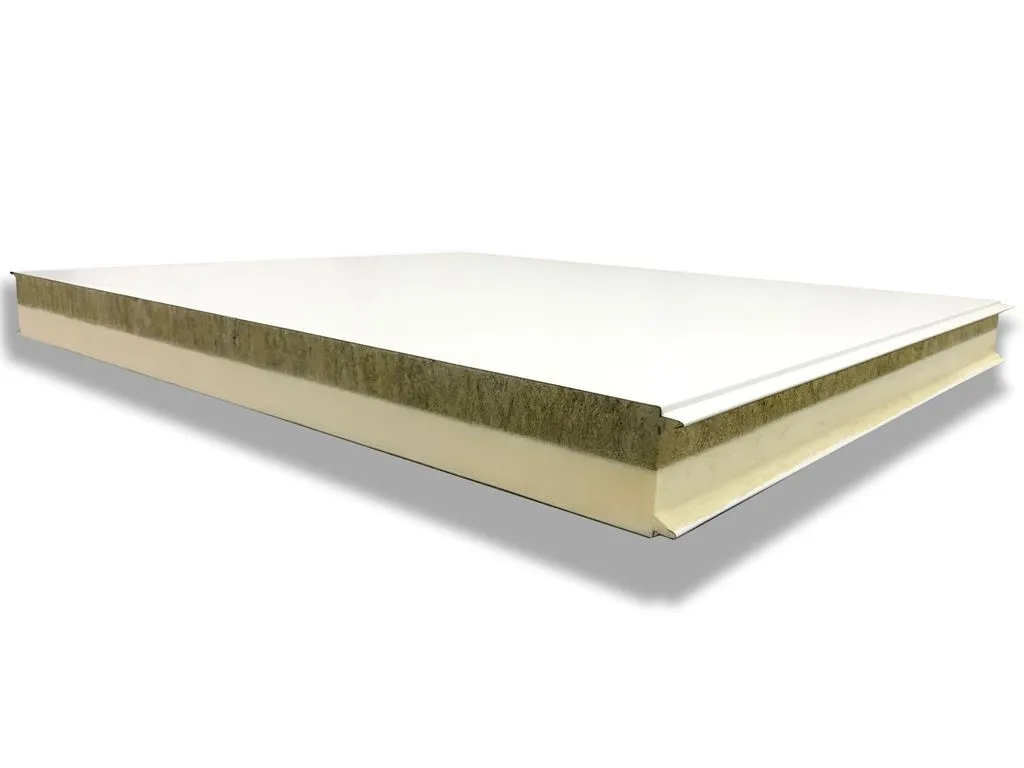

PH Insulation, the largest manufacturer of sandwich panels with polyurethane and polyisocyanurate in Russia, has reduced equipment changeover time for the production of PIR Plita® insulation boards by 40% through implementation of SMED system. Currently, the production lead time for PIR Plita® is only 14 days.

The Single-Minute Exchange of Dies (SMED) is a lean manufacturing technique aimed at reducing the time it takes to switch from one production process to another.

As part of the SMED initiative, PH Insulation has upgraded the equipment for the production of PIR Plita® on its second continuous line. New milling machines have been installed, allowing for an instant transition from PIR Plita® without L-shaped joints to PIR Plita® boards with L-shaped joints and back, without stopping the production process. Previously, this changeover took 30-40 minutes

The implementation of SMED has become a significant milestone in realizing lean manufacturing at PH Insulation's production facilities. The SMED project was executed in phases. First, regulatory documents were developed to standardize changeover times for different product types. Employees then underwent training in the SMED methodology, included both class studies and practical workshops. The next step involved a thorough analysis of current processes, which led to the decision to upgrade the equipment.

PH Insulation continues to assess the effectiveness of the implemented solutions and further improve business processes to further reduce changeover times. In the near future, the SMED manufacturing principles will be applied to the PH Insulation’s first continuous line that produces sandwich panels with PIR Premier core.