In 2020 PH Insulation has reduced CO2 emissions by 9 tons using solar energy and recycled 37 tons of materials: paper, cardboard, scrap metal.

Sustainable development is the fundamental principle which guides PH Insulation in manufacturing the most advanced insulation materials for smart temperature control.

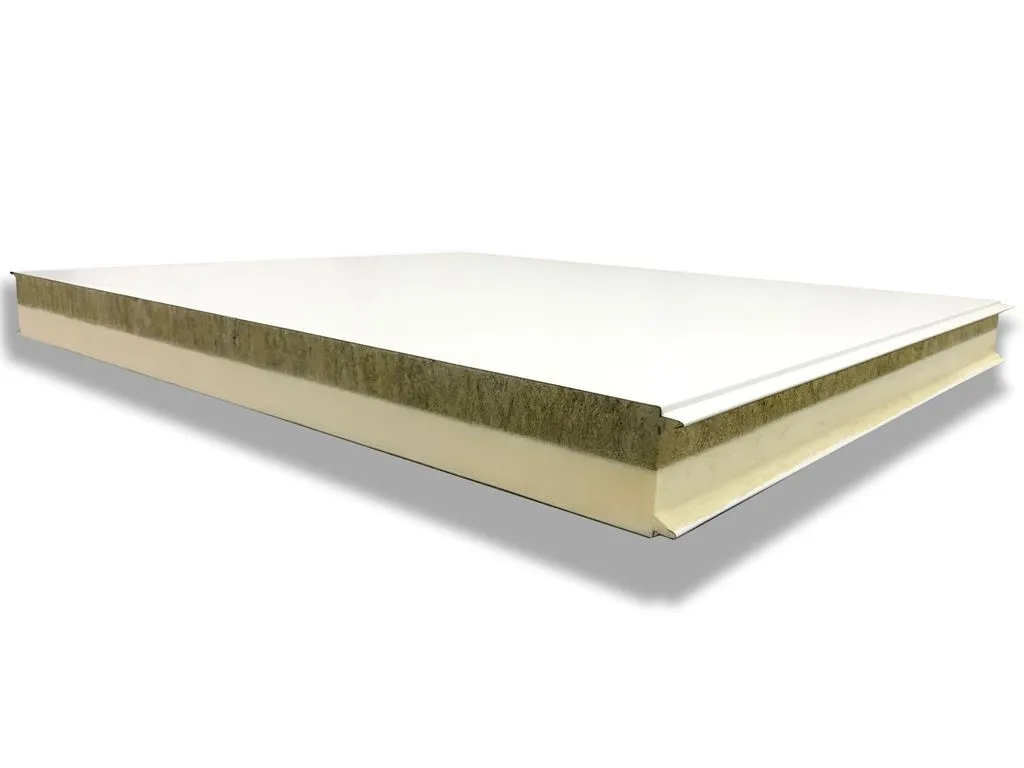

“The concept of sustainability and our commitment to reducing environmental impact are at the core of our activities. Based on these principles, PH Insulation manufactures sandwich panels with the polyisocyanurate PIR Premier core, the most advanced and energy efficient insulation material of today – to save energy and cost for operating buildings, refrigerating chambers,” said Andrew Kryzhanovskiy, Director for Manufacturing at PH Insulation.

“PH Insulation pursues reducing environmental impact in two ways. The first is to increase the energy efficiency of our products, the PIR Premier system and to encourage our partners to use renewable energy sources at their facilities. The second is the smart use of resources during manufacturing.”

Back in 2006 PH Insulation has installed the 27 kW wall solar station at the wall of its production line building. In 5 years, the solar system has allowed PH Insulation to reduce CO2 emissions by 89 tons. The solar power station was designed and installed by SolarOn, the first manufacturer of solar panels in Armenia.

1.jpg)

Since 2018 PH Insulation is using a hydraulic baling press to form recyclable cubes from waste paper. The paper is then sent for recycling to Sukhonskiy Pulp and Paper Mill in Vologda region, which makes hardboard and fibreboard out of it.

The scrap metal leftovers from the production of sandwich panels and refrigeration doors PH Insulation moves over to its partner, NLMK Group, for upcycling into metal, which returns to the PH Insulation factory to become new sandwich panels.

PH Insulation implements other initiatives to save natural resources:

-

PIR Premier is reused to create Kroshka PIR multi-purpose insulator,

-

PH Insulation encourages its partners to switch to electronic document management system to reduce the use of paper,

-

PH Insulation’s employees are collecting the old batteries to take them for recycling to collection points,

-

according to PH Insulation corporate rules, employees are encouraged to turn off computers at the end of the workday

For more information about the energy efficiency of PH Insulation products and solutions for the use of green energy visit the website profholod.com.