You can build fast and energy efficient production facilities or warehouses, and even residential buildings with many types insulation, but how do you know which fits your project best?

This article is about PIR vs EPS.

Both PIR and EPS are rigid insulation materials used as the insulation cores of sandwich panels. It may seem that the two materials share a number of similarities but both have their own characteristics and are actually very different.

Technology

Polyisocyanurate or PIR is a fireproof insulation material, derived from polyurethane. The PIR sandwich panels are manufactured on the continuous lines and the space between the metal sheets is filled with fireproof polyisocyanurate foam. This process makes the insulating layer of sandwich panels homogeneous and improves PIR panels’ strength and thermal properties in comparison with EPS-core panels.

Expanded polystyrene or EPS is a rigid insulation, manufactured by expanding a polystyrene polymer. The polystyrene beads are expanded into foam with steam, then dried, stabilized and formed into EPS blocks. In the production of EPS insulated panels expanded polystyrene is cut in the form of lamellas and glued to the metal facings, which negatively affects the strength and thermal insulation characteristics of the panels.

Thermal Conductivity

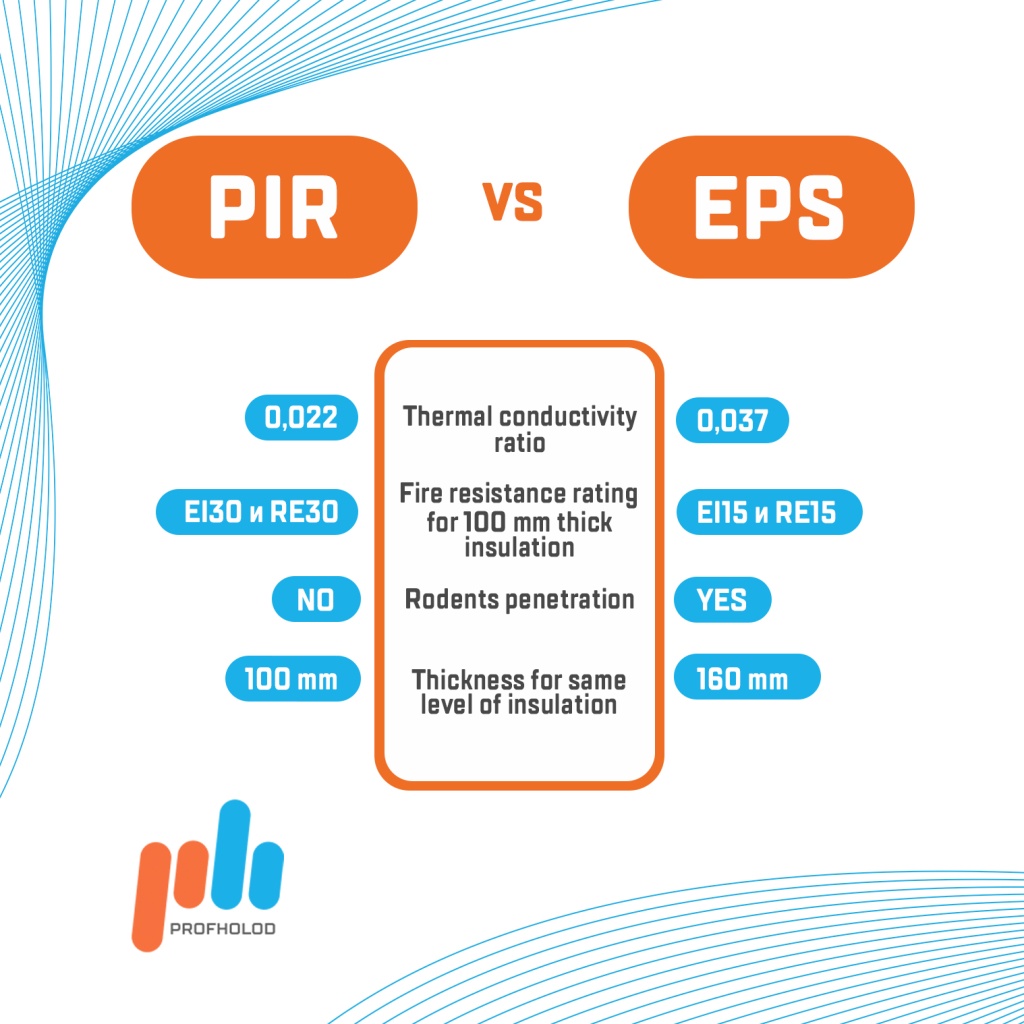

The first thing you look at in insulation is its energy efficiency. PIR panels have a thermal conductivity of 0.022 W/mK — lower than any other insulation in the world. The thermal conductivity of EPS is around 0.037 W/mK.

The lower the value, the better it insulates! So under the same weather conditions a building made with sandwich panels with polyisocyanurate foam will save heat and cold by 68% better than a building made with EPS panels. And when you choose PIR sandwich panels you can save on heating or cooling.

Thickness

Due to the low thermal conductivity, a 100 mm thick PIR Premier sandwich panel will save the cold or heat just as well as a 160 mm thick EPS panel. This means that sandwich panels with PIR will save you 60 mm of usable area.

Reaction to Fire

Fire resistance values of wall and roof PIR sandwich panels 100 mm thick are EI30 и RE30. EPS panels have EI 15 and RE15 fire resistance values for any thickness of insulation. This means that in case of fire, PIR sandwich panel will stay intact to maintain its load-bearing capacity and integrity for 30 minutes. Panels with polystyrene will lose these properties after 15 minutes.

Moisture resistance

Both PIR and EPS provide same level of resistance. They are made of closed cells, so they do not absorb water.

Resistance to Rodents

PIR is a solid closed cell material with rigid structure, so rodents do not eat it. EPS is formed of spherical beads that are fused together using steam — it's softer and not as dense as PIR, so rats and mice are tempted to nibble them.

If you have more questions about PIR and EPS, you can consult our engineers. Just send us an email – and we will get back to you the same day. We have been on the market since 2005, so we know everything about choosing the right insulation and saving the costs of your project.