Key points:

- PH Insulation marks a milestone: the company's factory in the Moscow region, Russia, has produced 20 million square meters of sandwich panels

- In 2021 PH Insulation insulated products are used in 26 countries around the globe

- PH Insulation will increase production by digitalization, constant interaction with customers, new inventions in the R&D Center

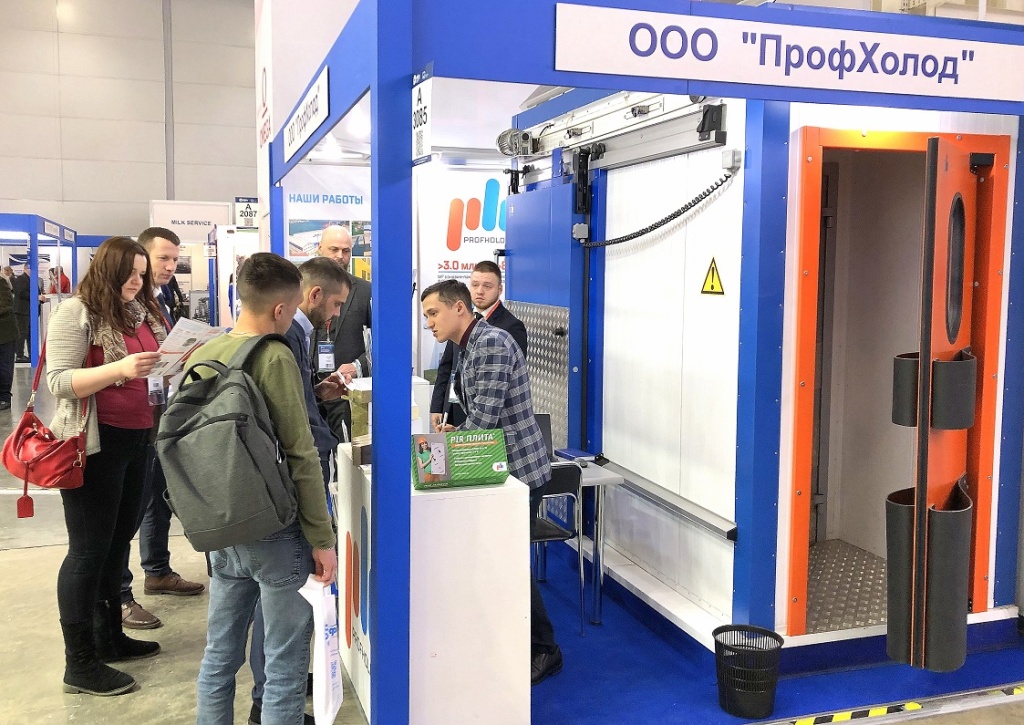

PH Insulation, ProfHolod in Russia, has manufactured 20 million square meters of sandwich panels. The jubilee 20-millionth square meter of sandwich panel has been produced on the first PH Insulation’s continuous line. The core of the sandwich panel – PIR Premier, thickness – 80 mm, length – 7380 mm, the metal – stainless steel AISI 304.

_2.jpg)

The sandwich panel will be used by a company in Moscow region that produces ready-to-eat food products.

16 years ago, in 2005, PH Insulation has entered the market producing sandwich panels with polyurethane foam. Today PH Insulation manufactures sandwich panels with three types of insulation on two Italian continues lines, PIR Plita® boards and 15 types of refrigeration doors. PH Insulation products are used in 26 countries, including the EU member states, the U.S., the Middle East, Africa, and Asia-Pacific.

Thermal conductivity of sandwich panels with custom-made polyisocyanurate PIR Premier is registered at 0.0194 W/m*K by the Technical Center Laboratory at Elastokam LLC—a joint venture between Nizhnekamskneftekhim and BASF Polyurethans GmbH.

"The significant milestone that we have achieved in 16 years and the geography of our supplies is a tangible proof of existing demand for our products all over the world and its perfect quality. What we have accomplished today is based on a large, well-coordinated work of my colleagues from the production department, research center, and the entire company.

For any manufacturer of sandwich panels, entering the formulation of the PIR foam is a totally new stage of development. We have created the PIR Premier system from scratch fully immersing ourselves in the details of how the polyisocyanurate foam is made. We have proceeded with commitment, or one might say stubbornness, to move forward facing even the toughest challenges.

We have a continuous pipeline of new opportunities to move forward and increase production through digitalization, constant interaction with customers, and new inventions provided by chemistry capabilities of our R&D Center."

Eduard Yarulin

PH Insulation Director for Production