Russian experts conducted a test synthesis at H&S Anlagentechnik according to ProfHolod’s technical requirements. The parties also discussed the details of control of input raw materials before industrial synthesis. German colleagues demonstrated the operation of a distillation column, one of the components of a reactor installation. The column allows to adjust the speed of distillation of low molecular weight products and return them to the reactor in accordance with the customized production process in ProfHolod.

ProfHolod is committed to improve its customized PIR Premier system to guarantee its customers the maximum level of physical and mechanical characteristics of polyurethane foam, including the most important indicator: thermal conductivity. Using the most modern reactor installation for the synthesis of polyethers in Russia, the company expects to surpass best world analogues in a number of parameters. The reactor is produced by H&S Anlagentechnik.

The launch of the reactor at ProfHolod is scheduled for the end of 2019.

H&S Anlagentechnik develops equipment and processing technologies for efficient and environmentally friendly storage, dosing, mixing and preparation of polyurethanes, for the processing of polyurethane and PET waste.

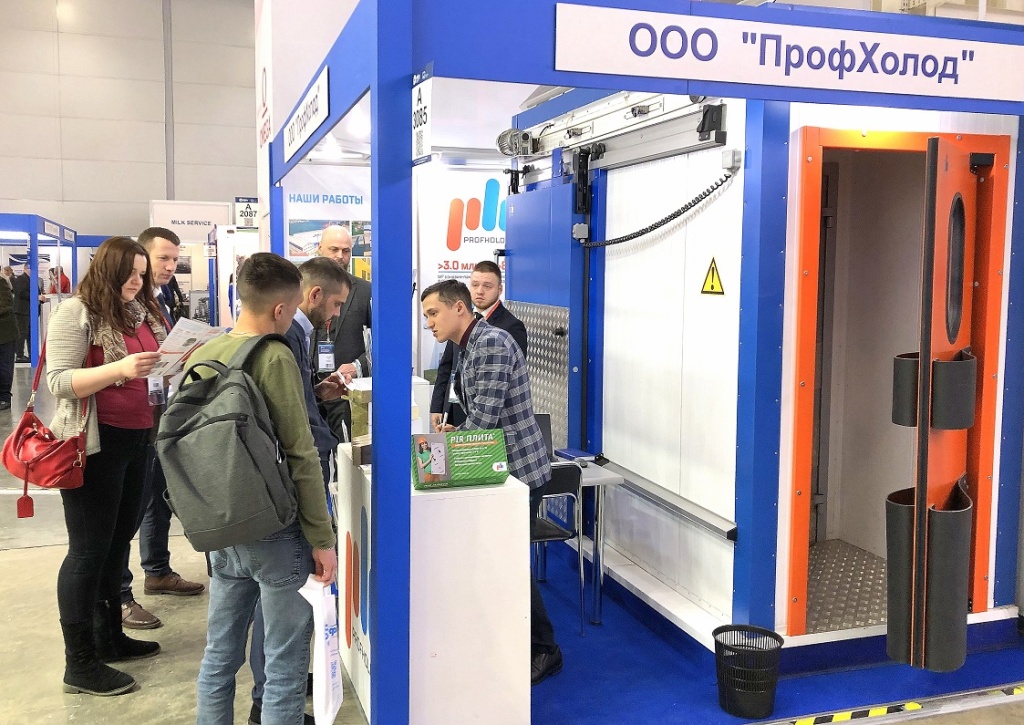

ProfHolod is the largest Russian manufacturer of sandwich panels with innovative polyurethane foam insulation.